PRODUCT

APPLICATIONS

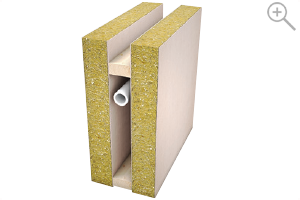

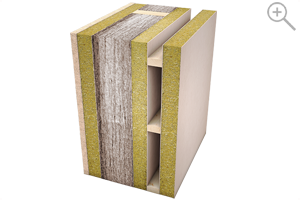

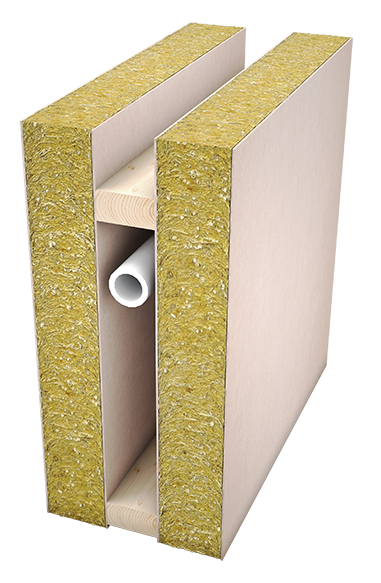

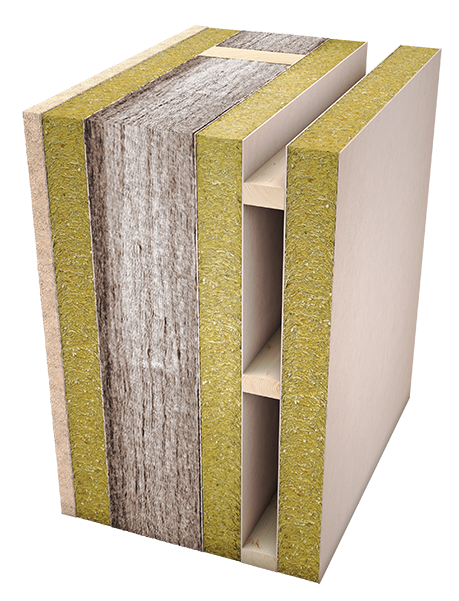

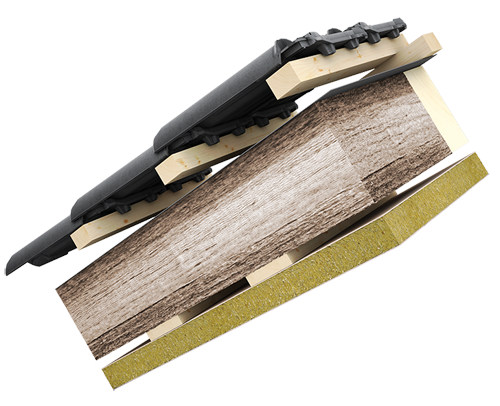

Ekopanely boards have a wide range of uses. They are suitable for the construction of new buildings, refurbishments, renovations, roof extensions and loft conversions. The versatile Ekopanely boards can be used for internal partition walls, for ceiling construction, cladding and also for all exterior work, making this product adaptable and very easy to work with.

ADVANTAGES

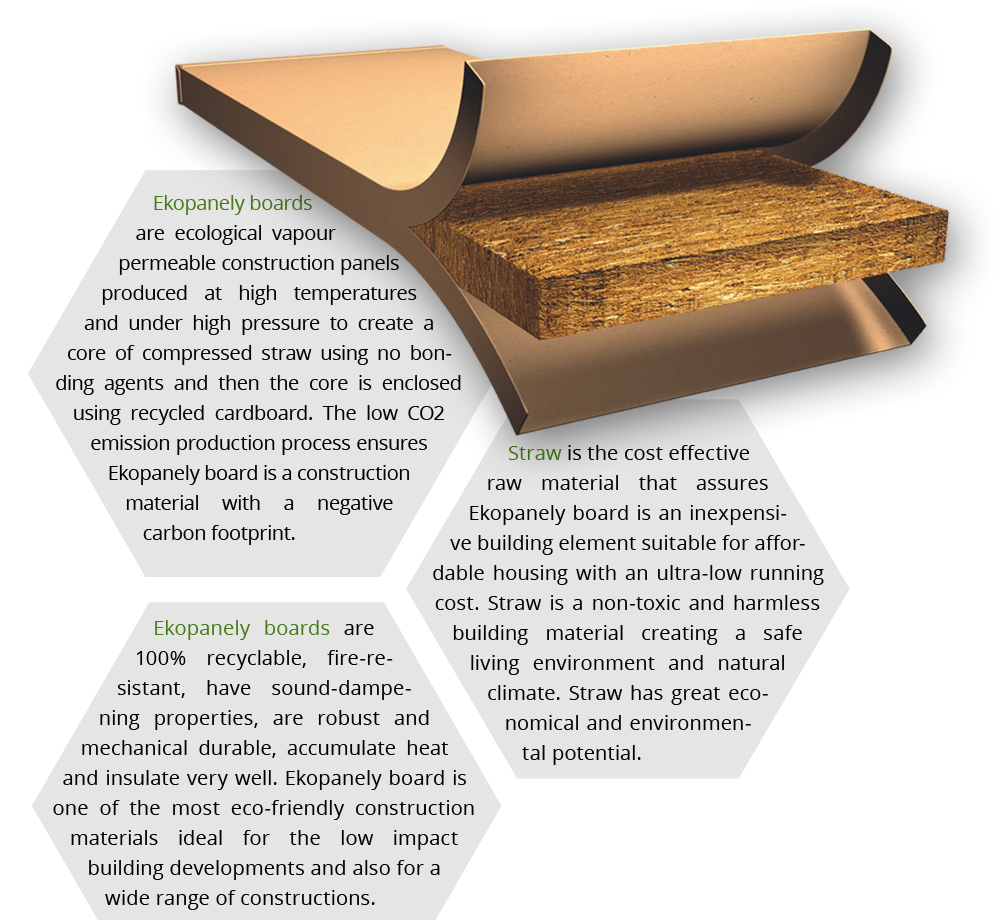

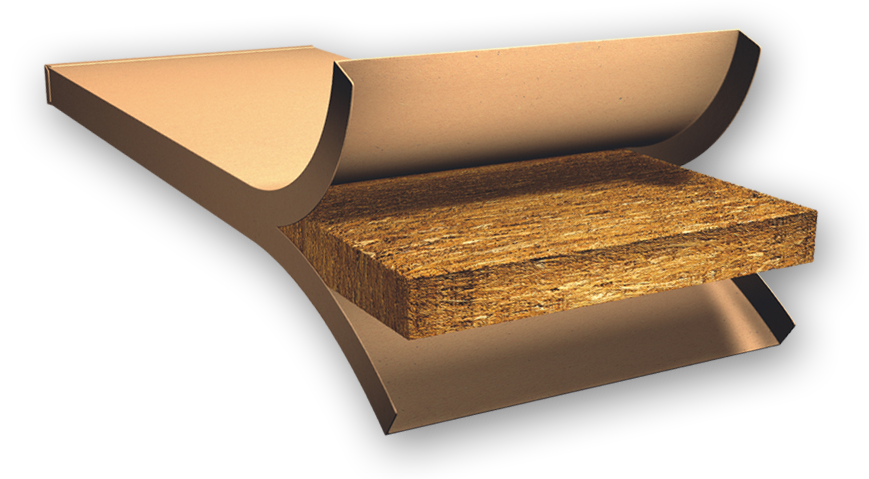

Compressed straw in Ekopanely boards enables to accumulate heat. Buildings made of Ekopanely boards cope better with fast changes in temperature and therefore save on heating costs. Furthermore, the heat capacity of Ekopanely boards is one of the main reasons why many construction companies and investors chose to use our product. Another very important factor is a quick completion. The efficiency of building using Ekopanely board systems reduces on-site construction time, which leads to significant savings in any construction projects. Also Ekopanely board has great insulation and acoustic properties and it is an ecological product made from a sustainable raw material (straw).

Heat accumulation

Acoustic absorption

Vapour permeable

High mechanical resistance

Insulation properties

Easy to install

Fire resistance

Custom size boards

100% ecological product

Recyclable

Harmless to health

Carbon capturer

FAQ

What is an Ekopanely board and where can it be used?

What is an Ekopanely board and where can it be used?

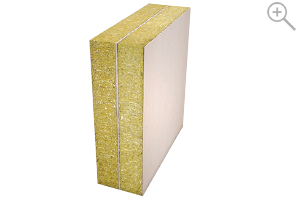

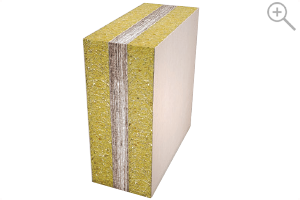

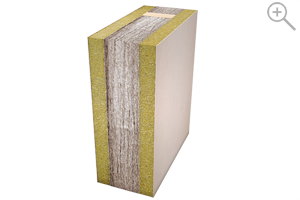

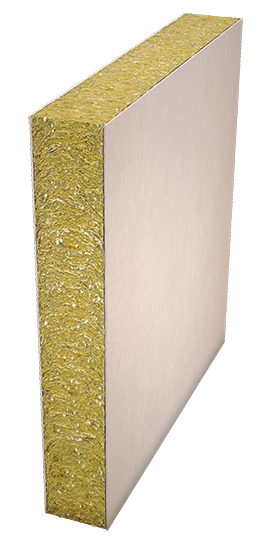

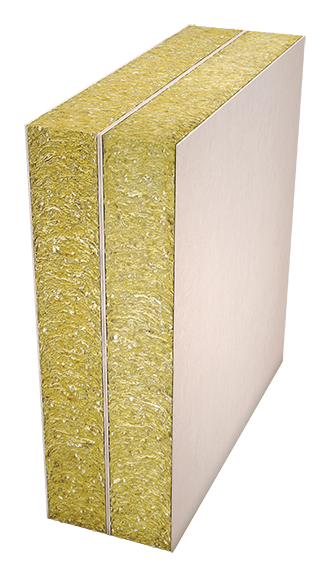

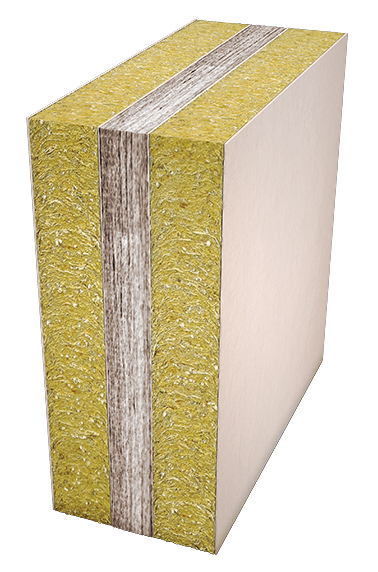

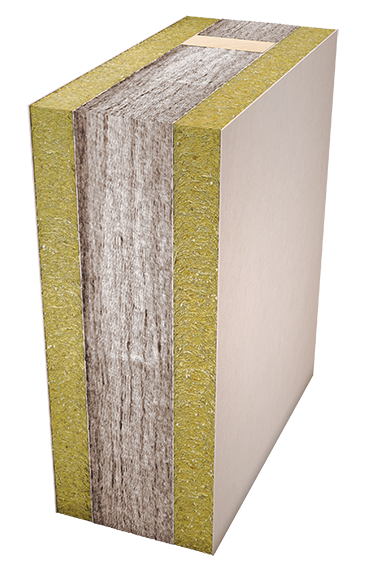

Ekopanely boards are ecological and vapour permeable construction boards. They are pressed at high temperatures and under high pressure to create a core of compressed straw using no bonding agents and enclosed using recycled cardboard. Ekopanely boards are 100% natural, fully recyclable building material suitable as a permanent part of a building.

Can an Ekopanely board burn? It is made from straw, after all!

Can an Ekopanely board burn? It is made from straw, after all!

It will not burn! The straw in Ekopanely board is pressed under very high pressure so that it contains very little of the air needed for a fire to burn. It is as if we wanted to burn a telephone directory in a fire place – this will also not burn without our help.

Can Ekopanely boards be eaten by mice or other rodents?

Can Ekopanely boards be eaten by mice or other rodents?

Threshed straw is used when produced Ekopanely boards, which is subject to high pressure when it is pressed in production. The straw core of the Ekopanely board is enclosed in three layers of recycled paper. After an Ekopanely board is installed into a structure, the surface is penetrated and a final surface finish is applied, which does not attract rodents.

How do Ekopanely boards cope with humidity?

How do Ekopanely boards cope with humidity?

After the Ekopanely board has been pressed, micro-pores are created in its core, which absorb air humidity. The panel retains this humidity until the temperature conditions around the Ekopanely board change for the better. The Ekopanely board then releases the humidity, moistening the air inside the room.

What is the lifetime of a house made from Ekopanely boards?

What is the lifetime of a house made from Ekopanely boards?

Dry straw pressed to form a panel can last for up to 100 years. This has been proven by experience from the first panels made in England, which were used to build economical prefabricated houses from 1942 to 1960. These houses are now 70 years old and still properly serve their purpose.

Is it complicated to install Ekopanely boards?

Is it complicated to install Ekopanely boards?

Installing an Ekopanely board is not a complicated process. Although it is a panel system, the basic technological procedures must be followed. Therefore, every month our firm holds a training course, providing trainees with all the information they need and a training certificate is given. Our firm also provides technical consultancy as standard. If interested, do not hesitate to contact us.

GALLERY

Proof of the quality and increasing popularity of Ekopanely boards can be seen in the many low-energy wooden buildings and turnkey houses. In Central Europe we have built more than 600 buildings and countless other applications. We have selected a few of the many references for buildings in which we have used Ekopanely boards. Our experience covers a range of projects, from building partitions to complete houses.

CONTACT

EKOPANELY SERVIS s.r.o.

Jedousov 64

535 01 Přelouč

Czech Republic

tel: +420 466 972 421

e-mail: export@ekopanely.com

Ekopanely Global Website

Ekopanely Global Website